|

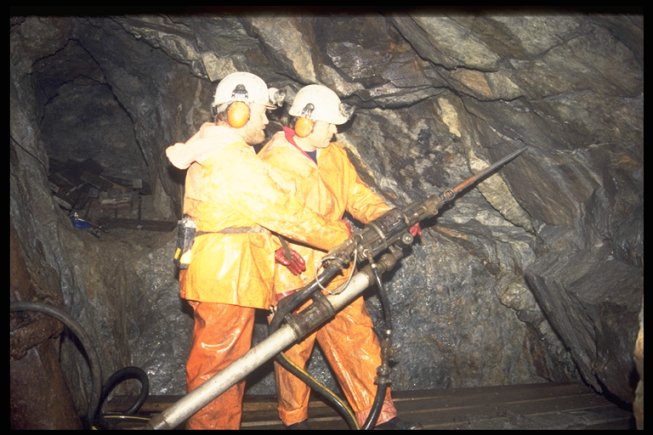

Terry and Les drilling in the upper Welsh shaft using a Holmans 303 rock drill. The machine works on compressed air whilst water is pumped up though the drill steel to flush out the hole and keep the dust at a minimum. Two meter long high tensile stainless steel bolts have been resin fixed into the shaft wall for the purpose of giving the water pressure engine support until the timbers can be replaced. Each hole can be drilled in about one and a half minutes and a total of six fixings were needed. |